|

|

|

|

| Heat Resistant Camera (Installed outside of Furnace)/HRS series |

Product Profile

|

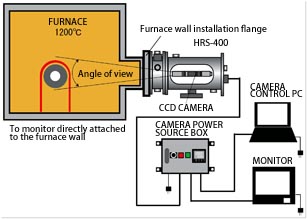

| The cameras of HRS

series are designed to monitor inside the furnace, through a furnace wall

window, if the temperature around the window is lower than 150℃. With optional equipment, it enables

you to monitor molten steel/ metal continuously even in extreme heat conditions

(1800℃). It gets mounted directly to the furnace wall, so no window glass is needed. |

|

Features

|

| With optional air purge

hood, the camera enables you to take video images inside glass melting furnaces

or other furnaces that radiate much stronger heat. Our cooling jacket is exceptionally

small, lightweight and easy to handle. The camera’s various functions are

easily manageable with PC software. |

|

Intended purpose/ Applications |

| blast furnaces / glass melting

furnaces / monitoring for blast furnace casting floors / monitoring cupola top

/ monitoring of incinerator / various melting furnaces / various heat treatment

furnaces |

| Application 1 |

Application 2 |

|

|

※Click the picture to download PDF Application example ※Click the picture to download PDF Application example |

| Heat Resistant Camera (Inserted into Furnace) /FS series |

Product Profile

|

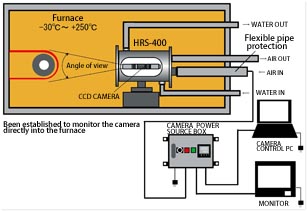

| The monitoring camera designed

for internal furnace use. (Patent number: 2891672). This is our original system,

and it enables the CCD camera equipped with a water-cooling jacket to be

inserted inside the furnace, and to take video images from directly within the

furnace. Compared with other relay lens or fiber-optic systems, the pictures and images of our cameras are of high

quality. Many of these products have been used in both domestic and overseas

glass production factories and steel plants. |

|

Features

|

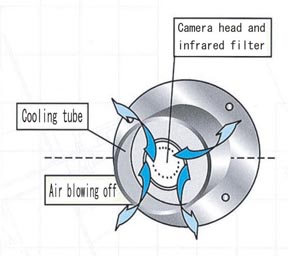

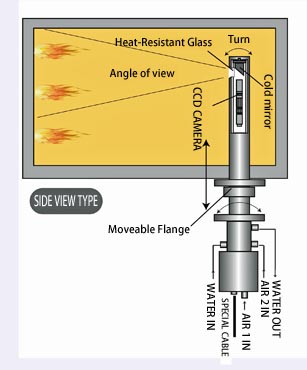

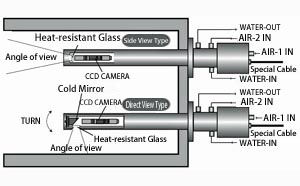

|

1. High-quality image possible, as images are taken from directly within the

furnace.

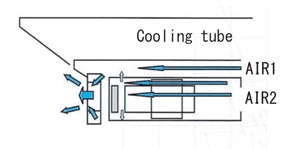

2. CCD camera/lens is

located several millimeters from the jacket window. Although there is no

shielding between object in furnace and CCD camera/lens, the cooling jacket

keeps the temperature around the lens at 40℃ or

under, protecting against the furnace

temperature of 1000℃.

3. This product is capable

of 24 hour, 365 day per year continuous operation by constantly supplying the

proper amount of cooling water and purged air.

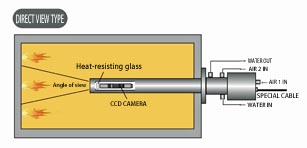

4. There are direct view

type and side view types. You can choose between them, according to your purpose.

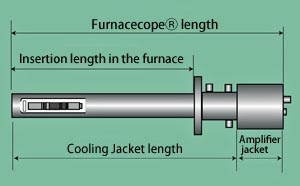

5. The length of inserted portion in the furnace of Furnacecope® can be customized to your request.

6. Air flow prevents the camera lens from dust

adhesion.

|

|

| Features 1 |

Features 2 |

|

|

|

|

|

Intended purpose/ Applications

|

blast furnace / glass melting

furnaces/ monitoring for blast furnaces / monitoring cupola tosp / combustion

conditions monitoring of incinerator / various Melting Furnaces / various Heat treatment

furnaces

| Application 1 |

Application 2 |

|

|

|

| ※Click the picture to download PDF Application example |

Model Number (Detail of FS model numbers) |

|

|

|

| FS-**-##-%%D/SWNL |

**=Limit temperature (12=1200℃, 15=1500℃) |

D=Direct View Type, S=Side View Type |

##=Length of inserted portion in the Furnace

(05=0.5m、10=1m) |

N=Camera controled by PC

W=Water-cooling amplifier jacket |

| %%=Outer diameter of inserted portion of the jacket (06=60.5mmφ) |

L=Built-in lighting |

|

|

|

Product Profile

|

| This camera has 5 times more

resolution (greater than 2 million pixels), than the 400 thousand pixel NTSC

cameras, which are currently mainstream in FA monitoring. The HD series has optical

10x, digital 12x remote zoom functionality. The Gig-E camera with C mount megapixel

lens enables you to monitor fine flaws, which are otherwise difficult to notice.

By protecting the camera in our cooling jacket, monitoring inside of ultra-high

temperature furnaces becomes possible. Gig-E cameras can also capture clear,

digital images, and easily send them to PC via LAN connection. |

|

Features

|

|

This is the full high-vision

Gig-E camera with a heat-resistance of more than 1000 degrees of the country

first.

1. Full High-Vision Camera (HD

series)

As HD series are capable of direct connection

with full high-vision monitors, the handling is easier than existing high-pixel

progressive cameras. The interlaced image output system enables it to work more

effectively against moving objects than others. The diverse image control

functions, like focus and zoom, are easily manageable with PC software.

2. Gig-E type Camera (G series)

Using an LAN cable, the

Gig-E type camera is capable of capturing image data to PC, from a maximum

distance of 100 meters.

The progressive CCD element, which is superior in

taking images of high-speed objects, enables you to monitor moving objects.

This was previously impossible by using the CMOS element. There are two options,

two million or five million pixels, depending on your purpose. The high-definition

images taken by this camera are quite useful for image analyses of the inside of

high temperature furnaces. Adjustment of camera images is controllable via LAN

connection.

|

|

Intended purpose/ Applications

|

| blast furnace / glass

Melting furnace/ monitoring blast furnace casting floor / monitoring cupola top

/ combustion conditions monitoring of incinerator / various melting furnaces / various

heat treatment furnaces. |

|

|

|

|

|